This article explores the 3 main applications of precision balls in the energy market, namely:

1) Precision balls and the field of renewable energies

In the era of energy transition towards cleaner and more sustainable sources, the renewable energy sector is at the forefront spearheading innovation in production.

As mentioned, in this increasingly important context, precision balls are proving indispensable to optimise performance and increase the longevity of systems.

Furthermore, the use of high-quality balls results in increased efficiency and reduced maintenance costs, which are crucial for long-term success and sustainability.

Specifically, precision balls for the renewable energy market are mainly used in:

Wind turbines

In wind turbines, precision balls are mainly used in ball bearings and spherical bearings that support both the rotor and the main axis of the turbine.

The use of quality balls in these bearings ensures a significant reduction in friction, enabling a smoother rotation of the rotor. This results in more efficient power generation and reduced operating noise, as well as extending the life of the turbine by reducing maintenance frequency.

For application in wind turbines, the use of unhardened stainless steel or metal alloy balls is recommended due to their high resistance to wear and corrosion. Alternatively, balls made of ceramic materials can be used due to their light weight and low density.

Solar panels

In solar panels, commonly known as solar tracking systems, precision balls are used to facilitate precise and smooth movements.

The rotation mechanisms enable the panels to follow the sun’s trajectory throughout the day, thus maximising light exposure and increasing energy efficiency. Therefore, the balls used inside the solar panels must ensure constant and smooth movement under various loads. In addition, they must be resistant to the atmospheric conditions and corrosion typical of the outdoor environments in which they are installed.

Stainless steel balls are commonly used for solar panels.

Another option is to use titanium alloy balls, which are known for their high corrosion resistance and strength, making them suitable for outdoor environments and extreme climatic variations.

Hydroelectric systems

In hydroelectric systems, precision balls are used in the bearings of water turbines.

In this instance, the role of precision balls is to improve the rotation of hydroelectric turbines by reducing friction. This is why it is essential that the balls are made of materials that can withstand the weight and pressure of water.

This is why balls with anti-corrosion coatings that can withstand continuous exposure to water and potential corrosive agents are preferable in hydroelectric plants. Another option are special balls made of composite materials or polymers.

2) Precision balls and energy storage technologies

With the increasing adoption of renewable energies, energy storage is becoming increasingly critical to balance the intermittency of these sources. In this rapidly evolving sector, which plays a key role in stabilising energy networks, precision balls are strategically important.

In fact, balls are used in a very wide variety of storage systems, improving their reliability and service life. Furthermore, the ability of precision balls to function under extreme conditions and resist wear and tear is crucial for their effective and durable maintenance.

More specifically, precision balls are used in the field of energy storage mainly in:

Flow batteries

In flow batteries, balls are crucial for a smooth and even flow of electrolyte liquids between the different battery compartments.

This is where precision balls are used in pump and valve bearings to enable precise flow regulation.

In flow batteries, the use of stainless steel or metal alloy balls is recommended as the ideal choice for this type of application. Indeed, these materials are resistant to corrosion caused by the electrolytic solutions in flow batteries and maintain their structural integrity even under pressure.

Compressed air storage systems

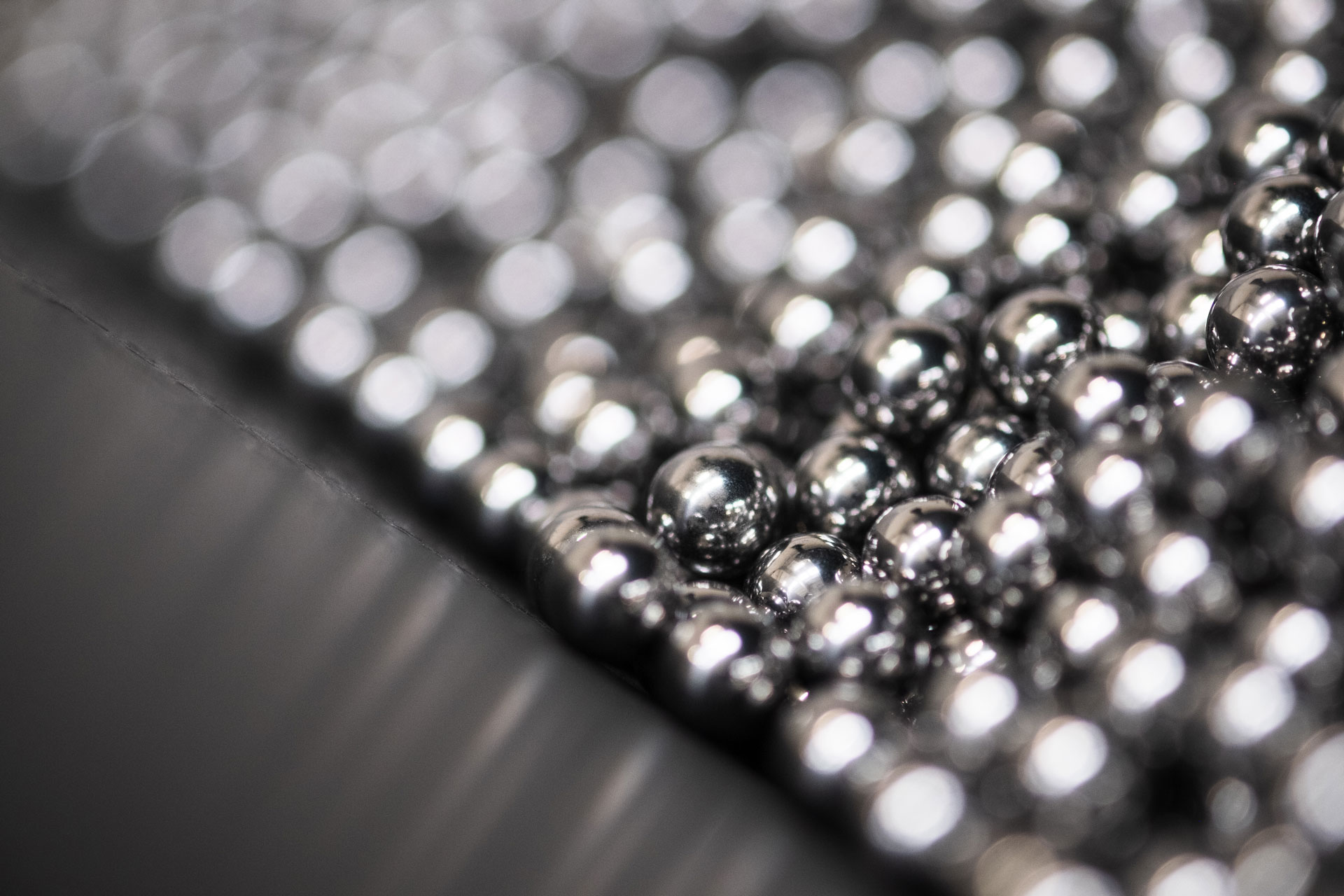

Precision balls in compressed air storage systems are essential to ensure tightness and smooth movement in compression and decompression mechanisms. Furthermore, these mechanisms often operate under high stress, requiring balls that can withstand significant loads without deforming or breaking.

High-quality, hardened stainless steel balls are recommended in compressed air storage systems.

This is because materials such as steel are known for their high resistance to deformation and fatigue, which are essential for maintaining operational efficiency under pressure.

Energy flywheels

In energy flywheels, precision balls are used to stabilise the rotation of the flywheel and to maintain or release kinetic energy effectively. Given the high speed of rotation and the large dynamic loads they are subjected to, the precision balls used for this purpose must be extremely wear-resistant and capable of operating with minimal friction.

For energy flywheels, these balls made of ceramic materials, such as silicon nitride balls are particularly suitable. These materials offer low density, low friction and superior strength, which are essential in reducing kinetic energy loss and improving the overall performance of the storage system.

3) Precision balls and the Oil & Gas sector

Despite the increasing focus on renewable energy, the oil and gas sector continues to be an essential pillar of the global energy industry.

In this context, reliability and safety are of paramount importance.

This is precisely why the ability of precision balls to withstand severe pressure and temperature conditions makes them irreplaceable components in these critical operations.

In the oil and gas sector, precision balls are mainly found inside:

Valves and pumps

In valves such as ball valves or butterfly valves, precision balls act as closing elements by blocking the flow when rotated. For these applications, the balls must be extremely precise for perfect sealing and leakage prevention. In contrast, in pumping systems, the balls are used in bearings and sometimes as non-return valves to ensure a unidirectional flow of fluid.

For valves and pumps, stainless steel/metallic alloy hollow balls are usually used because they offer excellent resistance to high temperatures and chemically aggressive environments. In addition, nickel-based alloys are particularly useful for applications requiring additional strength.

Extraction and transport processes

In extraction processes, precision balls are used in drilling machinery bearings in which they must withstand extreme conditions such as high pressures and intense vibrations.

In contrast, for transportation, the balls are used in systems such as pumps and valves where precision and reliability are crucial to prevent leakage and ensure safe transport of the extracted material.

In extraction and transportation processes, high-strength alloy steel balls are preferred for their ability to withstand high loads and resist wear under extreme operating conditions. In addition, cobalt-based alloy balls or stainless steel balls with high chromium content can be used for their durability and resistance in hostile environments.

Safety systems

Finally, precision balls can be used in safety valves or emergency locking systems where they are essential for quick and reliable response in critical situations.

Where resistance to pressure and high temperatures is essential, the use of balls made of chromium steel alloys or stainless steel with special heat treatment is usually recommended. Alternatively, for applications requiring non-magnetic materials, balls made of nickel or titanium-based alloys can be considered for their corrosion resistance and non-magnetic properties.

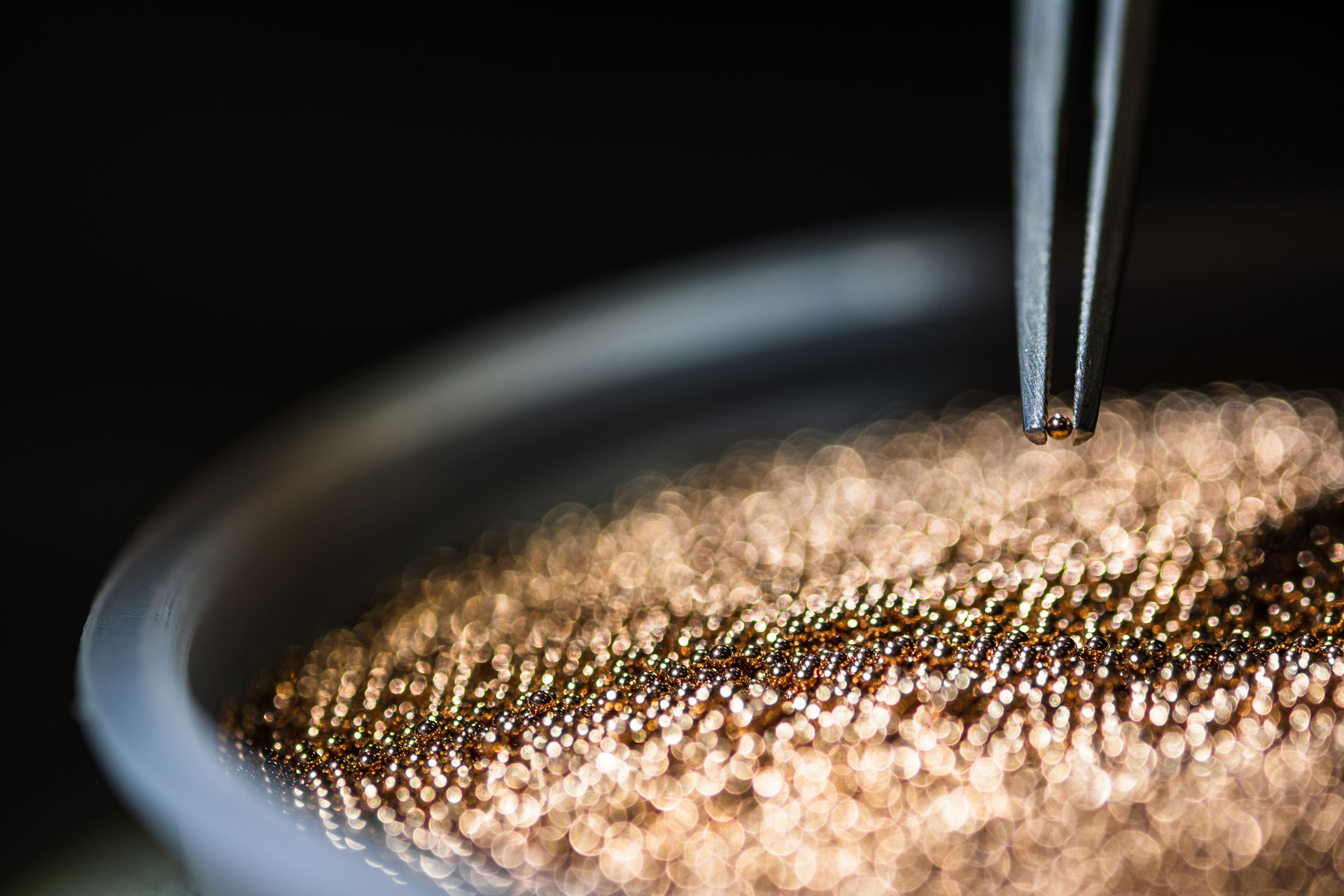

RGPBALLS: innovation and quality in energy balls

At the forefront of industrial ball production, RGPBALLS stands out for its dedication to technological innovation and production quality, especially in the context of the energy sector.

Our company has a firm commitment to research and development and is committed to producing balls that do not only meet, but anticipate the needs of the energy market. We focus primarily on the production of precision balls using high-quality materials and advanced manufacturing processes, which guarantee superior performance even under the most extreme operating conditions.

Furthermore, our experience and expertise with industrial balls allow us to offer not only high quality products, but also specialised technical support and advice.

Discover RGPBALLS innovation in the energy sector

Request your tailor-made solution now

20092 Cinisello Balsamo (MI) - Italy

P.I. / C.F. / Reg. Impr. 08678490965

N. REA: MI-2042305

Cap. soc. € 1.000.000 int. vers.

Please note that any particular and specific technical requirements must always be requested in advance during the quotation phase.