How

to select

Initial considerations for correctly selecting the most suitable product.

Aspects to be assessed

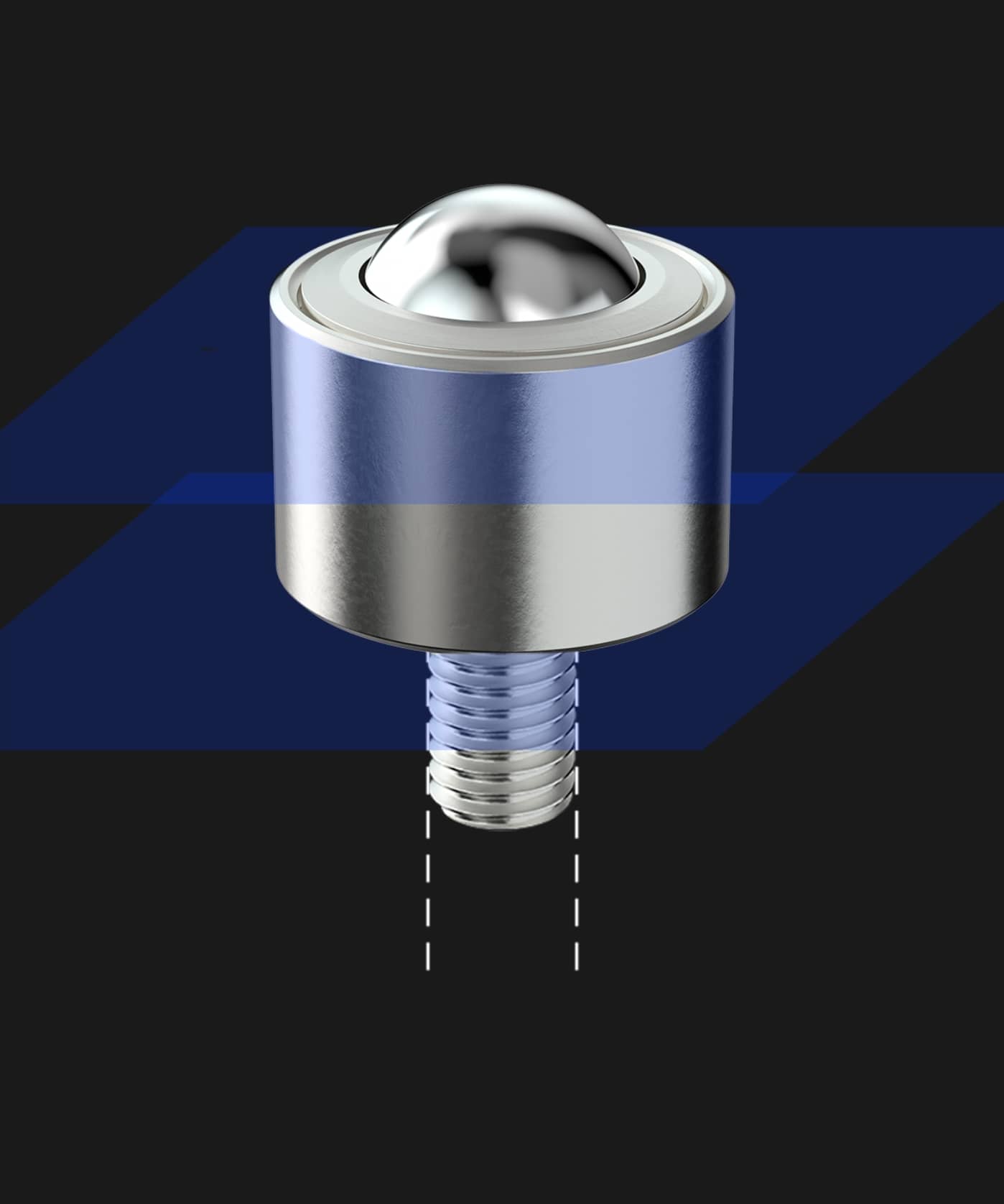

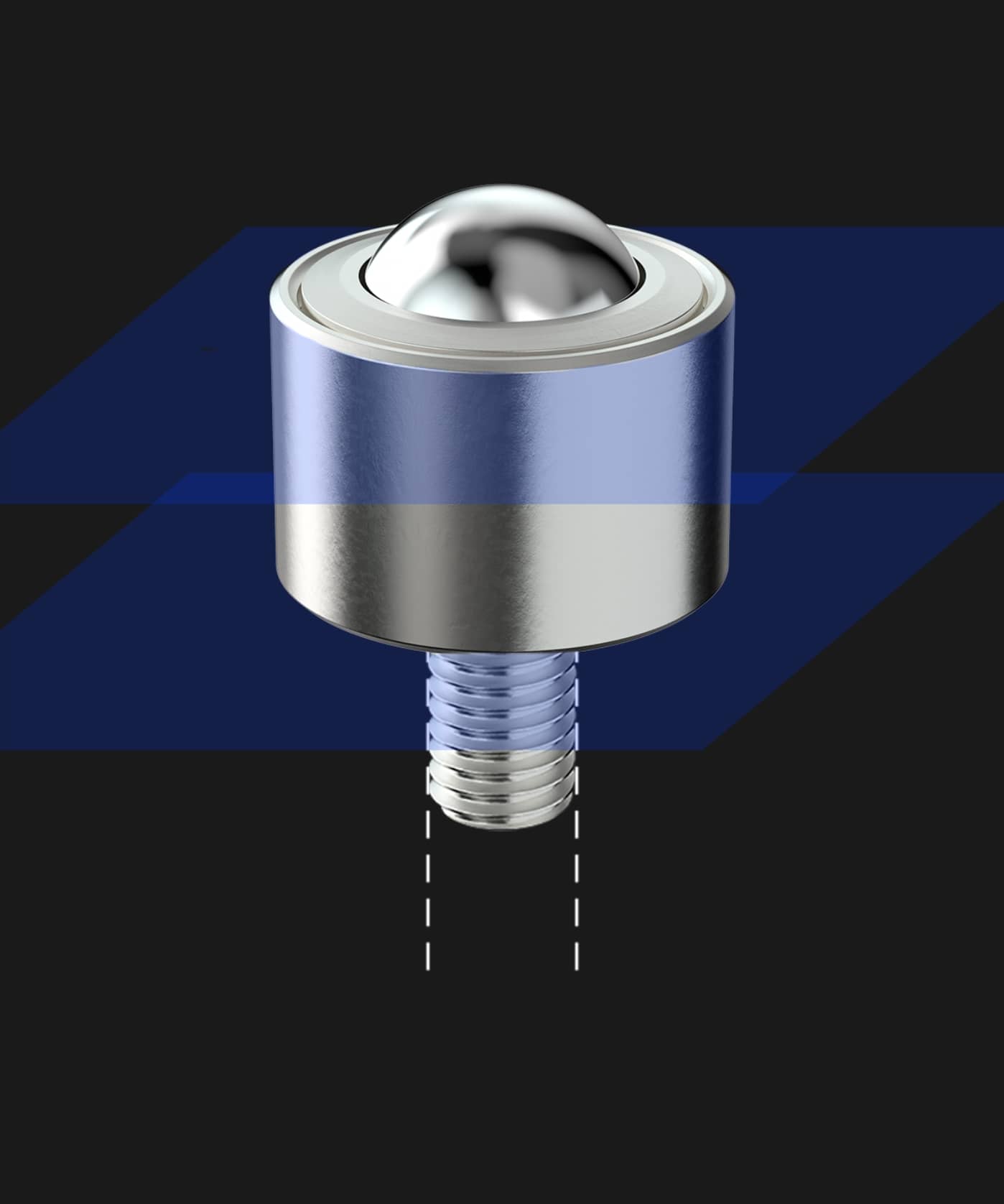

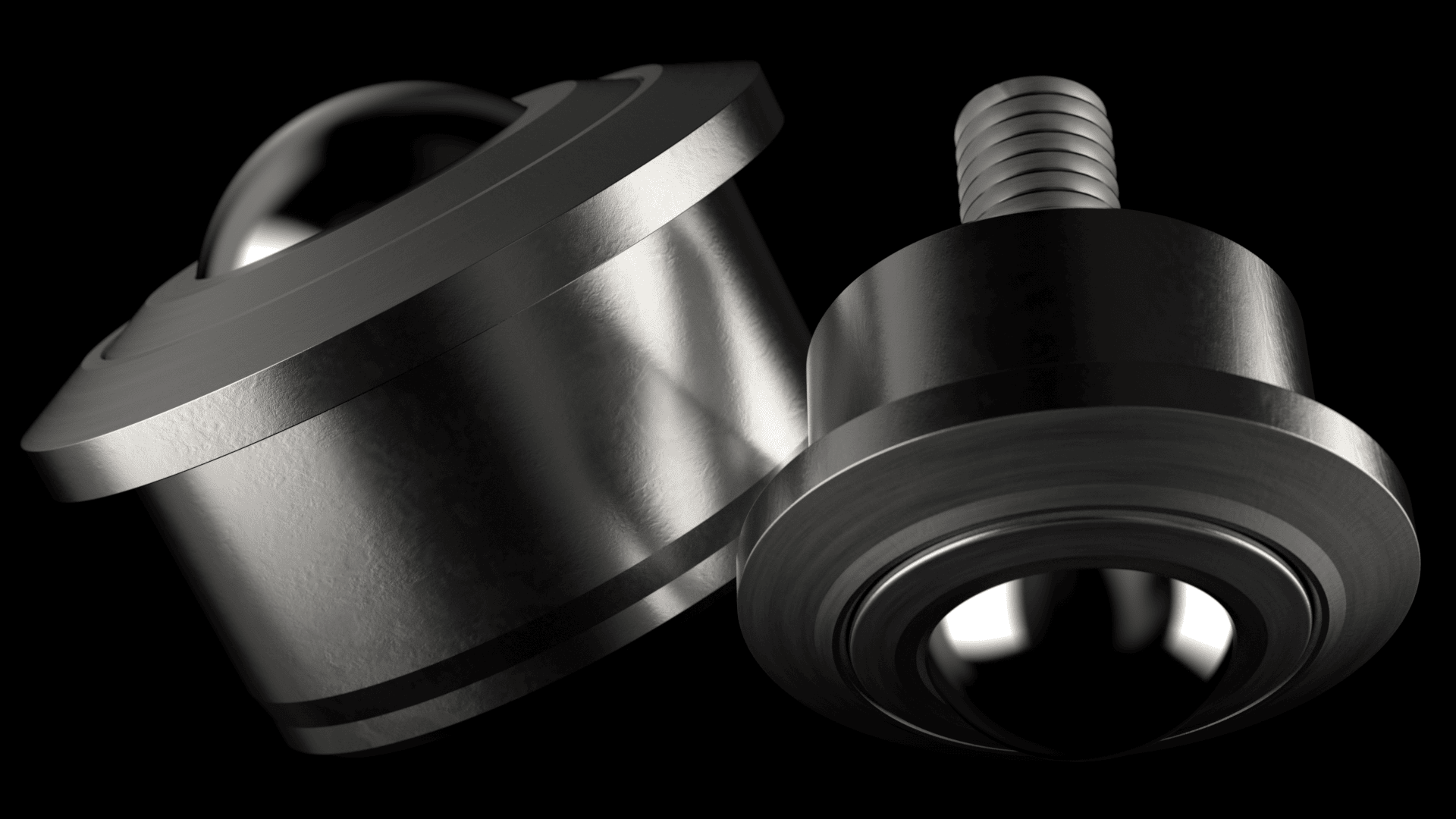

Position and assembly of the component

The product can be assembled with the load sphere facing upwards, downwards or according to the type of use required.

Consider the temperature to which the ball bearings will be subject

Depending on what type of material they are made of, the balls can react to loads in different ways.

Assess the environment of use

Different contaminating factors (dirt, dust, humidity etc.) Can influence the yield of the product.

Additional aspects such as speed, frequency and duration of the loads handled

Positioning

Fixing and positioning are performed with the usual insertion in pre-established holes or resting on the base, By means of screws and rivets in the versions with fixing holes or through internal or external threads.

Available

There are three types of ball bearings that are normally used:

On request

Addition of a fixing ring for additional stability control.

Fixed and detachable available.

Pre-lubrication of the ball bearing to aid preservation.

Felt seal to better protect the ball from impurities.

Specific requirements

Special made-to-measure balls

To cater for the widest possible variety of users and applications, other types of ball bearings can be supplied, subject to careful assessment, made-to-measure based on your requirements.

Our technical office is available to assess the feasibility of versions that meet the needs of the user and can advise the Client on the right choice of ball bearings to be used.

Ball transfer units

20092 Cinisello Balsamo (MI) - Italy

P.I. / C.F. / Reg. Impr. 08678490965

N. REA: MI-2042305

Cap. soc. € 1.000.000 int. vers.

Please note that any particular and specific technical requirements must always be requested in advance during the quotation phase.