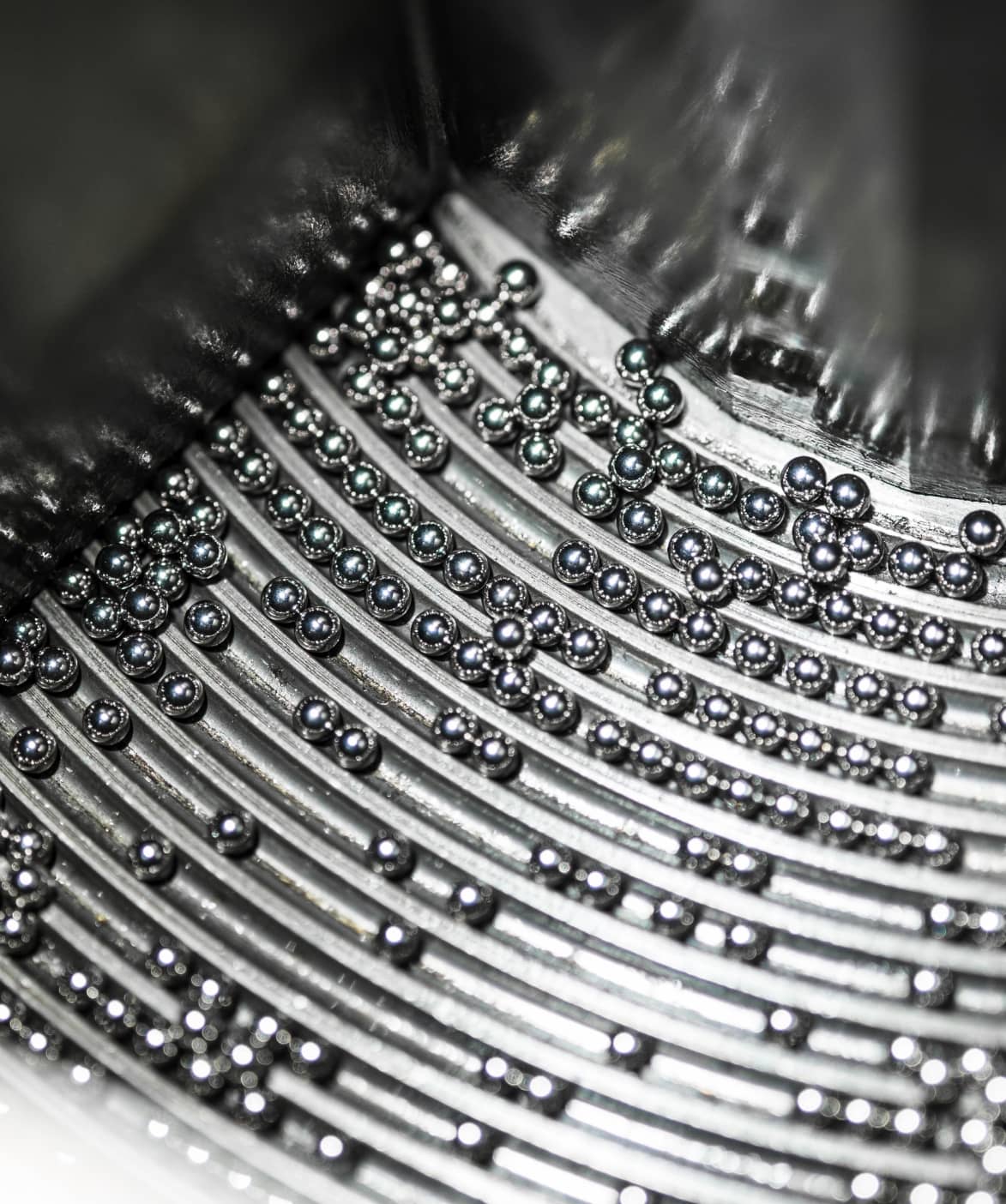

ZIRCONIUM OXIDE (ZrO2) BALLS

Refractory ceramic material balls, they provide excellent corrosion, wear and heat resistance. They improve their hardness when they are subjected to collisions. Yttrium doped Zirconia Oxide, they provide the best properties between ceramic materials in grinding and milling applications.

Special bearings, pumps and valves that operate in aggressive environments, check valves, flow meters, measurement instruments. They are used in the medical field (very pure material). Grinding and milling applications.

Other ceramic balls

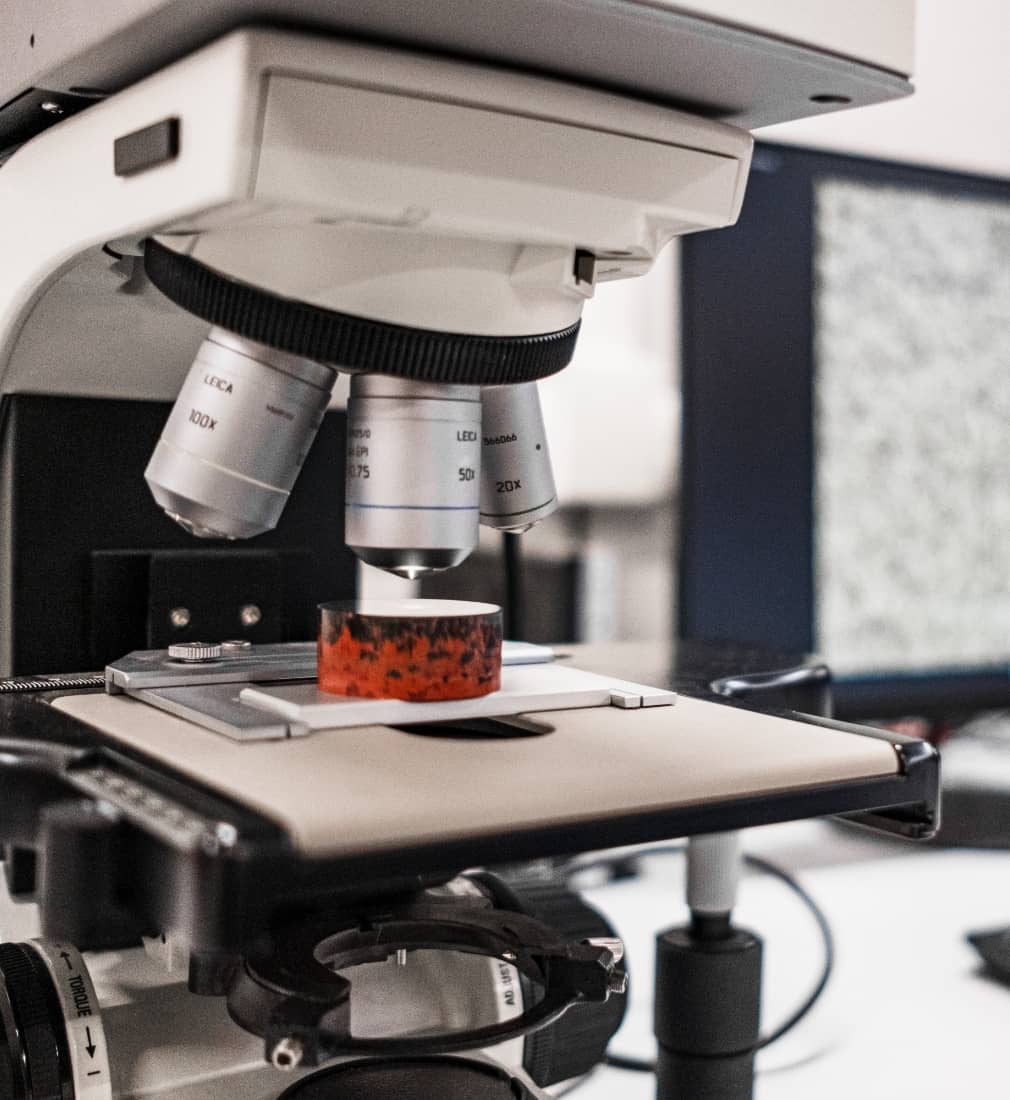

Quality

In-house metallographic and metrological laboratory for analyses of the microstructures of steel.

Speed

6,000 square-metre warehouse in a single location with the main sizes ready for delivery.

Precision

Custom diameters with 0.25 micron precision on request. In-house production and Made-in-Italy certification.

Quote

Take the first step with our project manager.

RGPBALLS srl contacts

Thanks for contacting us

You will get an answer soon

Our products

It all starts with a ball.

20092 Cinisello Balsamo (MI) - Italy

P.I. / C.F. / Reg. Impr. 08678490965

N. REA: MI-2042305

Cap. soc. € 1.000.000 int. vers.

Please note that any particular and specific technical requirements must always be requested in advance during the quotation phase.